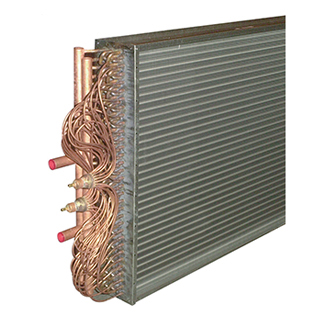

COIL SIZES

1 row to 12 rows deep Finned heights/widths up to 66” Finned lengths up to 144”

ALUMINUM FINS

Tempered aluminum fin stock Die-formed plate type fins 0.045” fin thickness at 9 to 16 fpi on 3/8” O.D. tube coils 0.006” fin thickness at 7 to 16 fpi on 3/8” O.D. tube coils 0.006” fin thickness at 8 to 14 fpi on 1/2” O.D. tube coils 0.010” fin thickness at 6 to 12 fpi on 1/2” O.D. tube coils 0.006” fin thickness at 8 to 14 fpi on 5/8” O.D. tube coils 0.010” fin thickness at 4 to 12 fpi on 5/8” O.D. tube coils

COPPER FINS

Tempered copper fin stock Die-formed plate type fins 0.005” fin thickness at 8 to 14 fpi on 3/8” O.D. tube coils 0.005” fin thickness at 8 to 14 fpi on 1/2” O.D. tube coils 0.005” fin thickness at 8 to 14 fpi on 5/8” O.D. tube coils

COIL TUBES

Seamless drawn copper 3/8” O.D. coil tubes x 0.0118” wall (rifled) or 0.014” wall (smooth) 1/2″ O.D. coil tubes x 0.017” wall (smooth) or 0.028” wall (smooth) 5/8” O.D. coil tubes x 0.020” wall (smooth) or 0.035” wall (smooth) Mechanically expanded into the fin collars for positive metal-to-metal contact Cupro-nickel 1/2″ O.D. tubes x 0.035 wall (smooth) Mechanically expanded into fin collars for positive metal-to-metal contact

HEADERS/CONNECTIONS

Type “L” copper headers up to 4” nominal diameter Copper and brass adaptors, sweat (plain) connections or Victaulic connections Control Devices premium quality distributors used on evaporator (DX) coils Sized to suit the application

COIL CASING

Galvanized steel casing 16 ga. standard Stainless steel casing 18 ga., 304 SS class 2B standard Drain pans when required Fully encased, slip & drive or end plates only

BRAZING MATERIALS

Copper brazing alloys with 6% to 15% silver content for maximum strength

TESTING

Fluid (water/glycol) and steam coils tested, under water, at 325 psig Refrigerant bearing coils tested, under water, at 500 psig; additional nitrogen charge test with digital instrumentation

CERTIFICATIONS

3/8” O.D. tube coils ETL certified to CSA C22.2 and UL 207 1/2″ O.D. tube coils ETL certified to CSA C22.2 and UL 207 1/2″ O.D. and 5/8” O.D. tube coils – CRN (Canadian Registration Number)

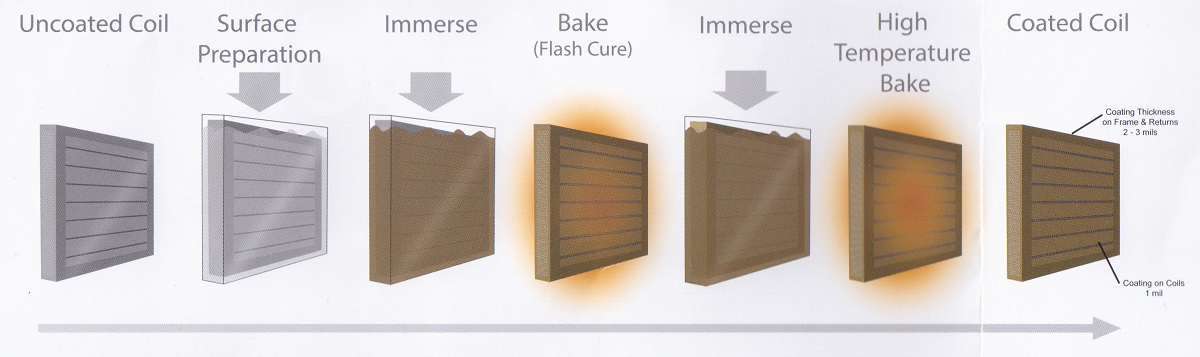

HERESITE CORROSION PROTECTION COATING

Heresite Phenolic Coating available and applied onsite, if specified.